Liquid Milk Processing Plant

Liquid Milk Processing Plant

Milk is widely considered as one of the world's most valuable protein food. As a raw material. It is available in various forms, and it is processed into an ever increasing variety of nutritional products. SSP offers Dairy Plant that includes small milk processing equipment for handling milk in litre capacity of 1K-5Lac litres per day. A number of products like ghee, butter, cream, toned milk, double toned milk, skimmed milk, can also be manufactured. Milk is first received in a dump tank from the road milk tankers. It is then chilled in a chilling unit to 4ºC. This chilled milk is then pasteurized in a milk pasteurizer and cream is separated from milk in by the cream separator to get skimmed milk. Milk is standardized depending on the requirement of toned milk, double toned milk, skimmed milk or full cream milk. The separated cream is further processed to manufacture ghee and butter. The pasteurized skimmed milk, toned milk or double toned milk is sent for packing in pouches in the packing machine for various capacities like ½ kg, 1 kg pouches. The plant will be in operation for 20 hours in a day.

Milk is widely considered as one of the world's most valuable protein food. As a raw material. It is available in various forms, and it is processed into an ever increasing variety of nutritional products. SSP offers Dairy Plant that includes small milk processing equipment for handling milk in litre capacity of 1K-5Lac litres per day. A number of products like ghee, butter, cream, toned milk, double toned milk, skimmed milk, can also be manufactured. Milk is first received in a dump tank from the road milk tankers. It is then chilled in a chilling unit to 4ºC. This chilled milk is then pasteurized in a milk pasteurizer and cream is separated from milk in by the cream separator to get skimmed milk. Milk is standardized depending on the requirement of toned milk, double toned milk, skimmed milk or full cream milk. The separated cream is further processed to manufacture ghee and butter. The pasteurized skimmed milk, toned milk or double toned milk is sent for packing in pouches in the packing machine for various capacities like ½ kg, 1 kg pouches. The plant will be in operation for 20 hours in a day.

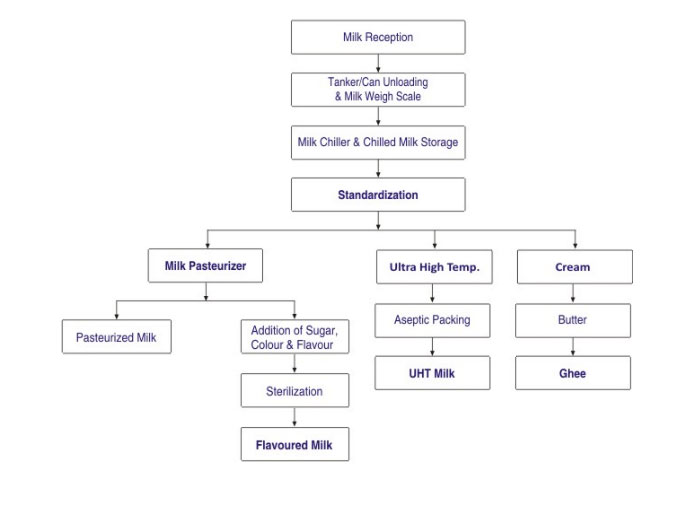

Block Diagram For Liquid Milk Processing :